Engineered Polymer Products - Sales

(F) 904.757.7116

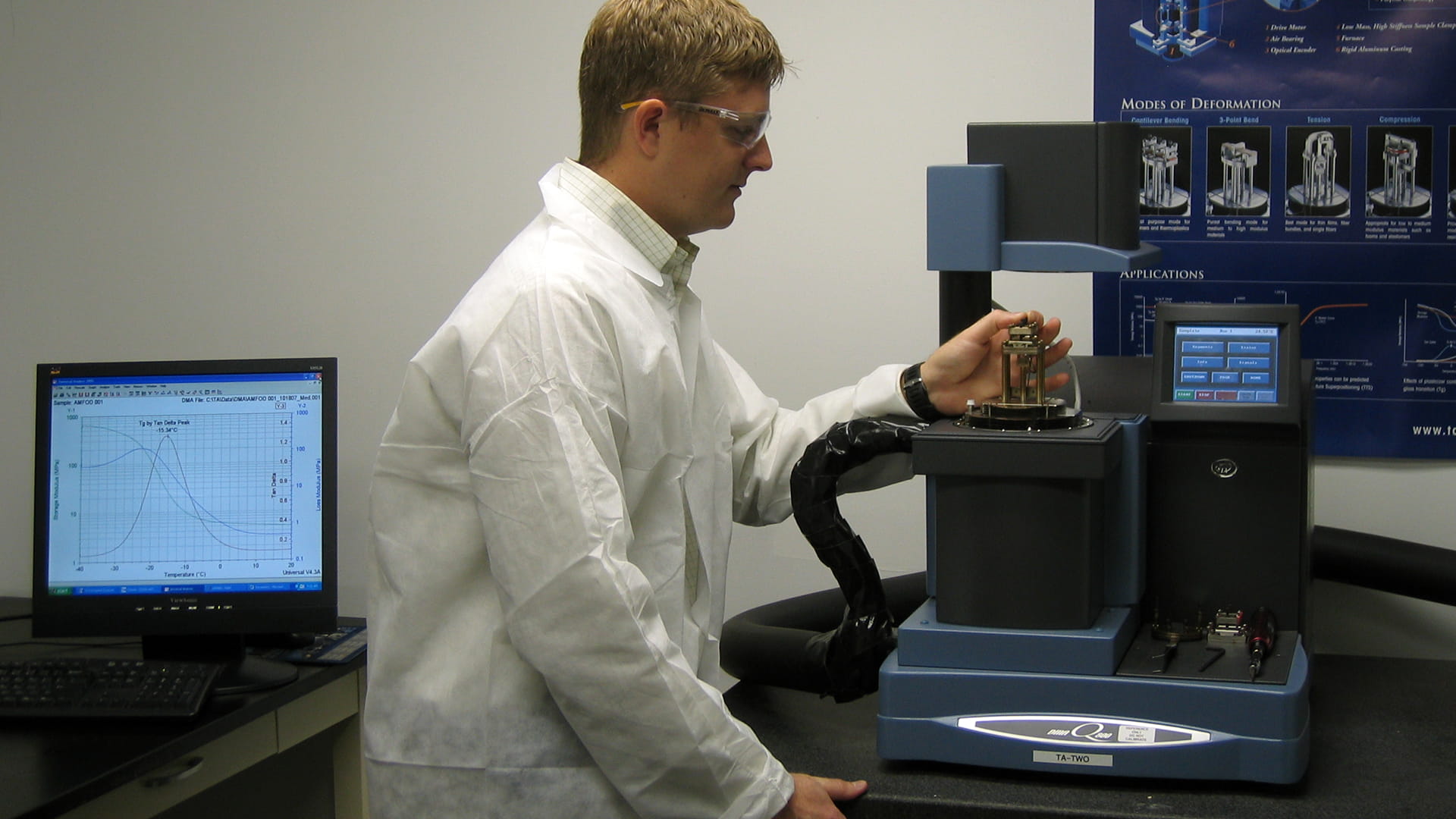

Our composite materials test laboratory is staffed with experienced composites technicians who can perform a variety of advanced testing.

Collins Aerospace offers the facilities, equipment and processes to support large- and small-scale homogenous and hybrid composites manufacturing.

Advanced materials and product testing capabilities include:

Types of tests available:

Our advanced material manufacturing processes include many that are unique to Collins Aerospace, using:

With Collins Aerospace, you’ll have the support of an outstanding, full-service engineering staff for unique, high-performance composite structures. We design structural laminates, composites and tools and provide analysis and tool fabrication.

Our full-service CAD department provides detailed drawing packages for all engineering designs and part details. To speed the prototyping of new structures, we use Patran and ABAQUS for finite element analysis (FEA).

Let us take your application from concept through prototyping/testing and into production. All of our products are tailorable to fit your exact specifications.

Specialties include:

Engineered Polymer Products - Sales