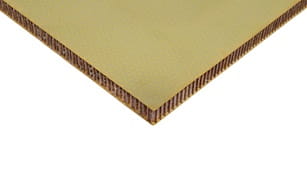

When choosing interior aircraft structural panels, Collins Aerospace’ comprehensive line of standard and custom honeycomb panels deliver safety, durability and weight savings. Through precise material and process selection, in-house experts evaluate the properties of the materials in customer designs and provide alternative solutions as necessary. These solutions can help reduce weight, increase strength and/or reduce cost.

Collins Aerospace offers strong in-house research and development services at our ISO 9001/AS9100 Rev D certified facility to support individual panel requirements, ensuring the end product is exactly what is required.

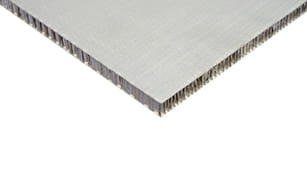

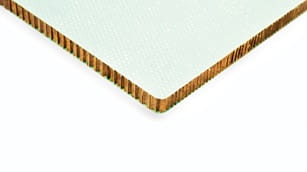

Flat & curved laminated honeycomb panels

Collins Aerospace’ standard product line includes more than 30 standard configurations of floor and interior panels. Additional configurations can be provided as required.

Standard panel thicknesses are held to an industry-leading +/- 0.010 inch tolerance, and are designed for durability that exceeds standard OEM requirements.

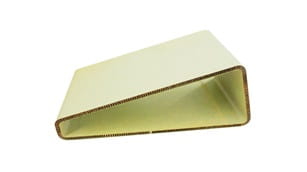

In addition to the line of flat panels, our oven-cure vacuum bagging process enables production shapes with complex curves, providing more flexibility in cabin design.

Integrated and optimized solutions

Many of Collins Aerospace’ advanced, integrated panel designs incorporate components embedded within the panel itself, from hinges and hard points to latches and electrical conduit. Whichever components are required, the proprietary processes ensure embedded components maintain their precise location throughout the layup and press processes.

Value-added services

As part of Collins Aerospace’ value-added services, Collins provides finished parts or part kits – packaged and delivered, ready for assembly. These services include:

- Computer numerical control (CNC) routing

- Edge closeouts and edge fill

- Insert installation

- Cut and fold