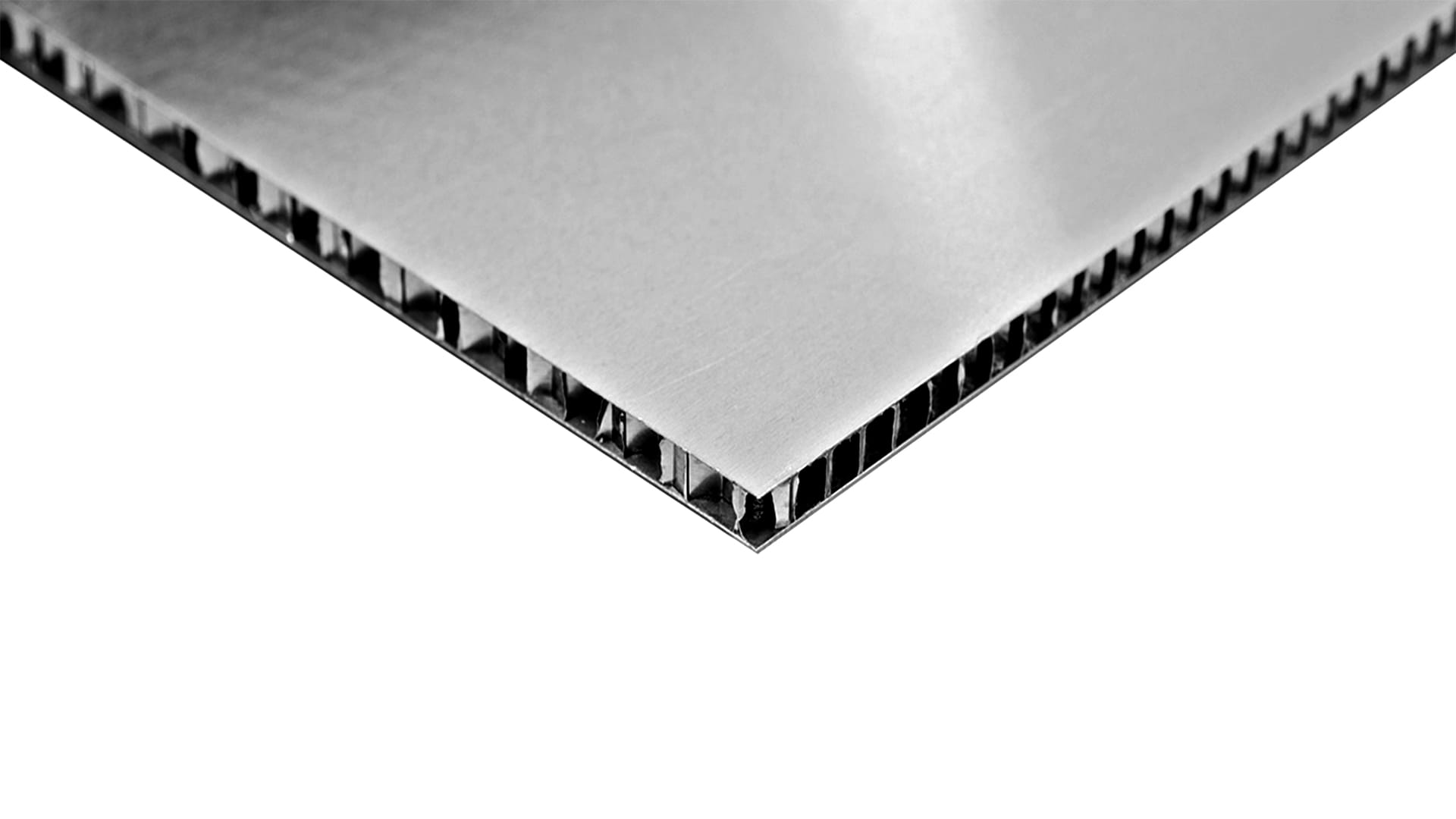

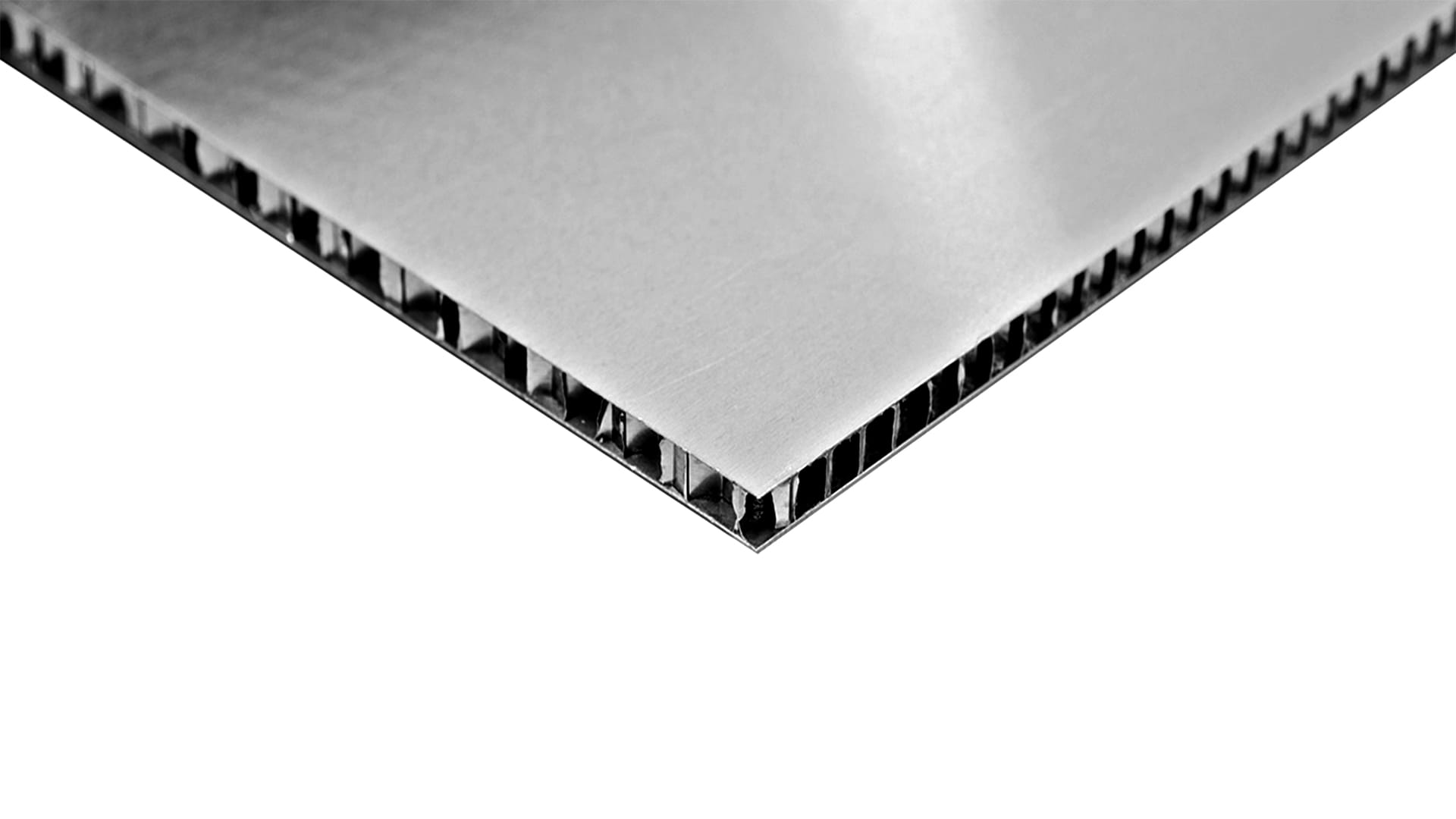

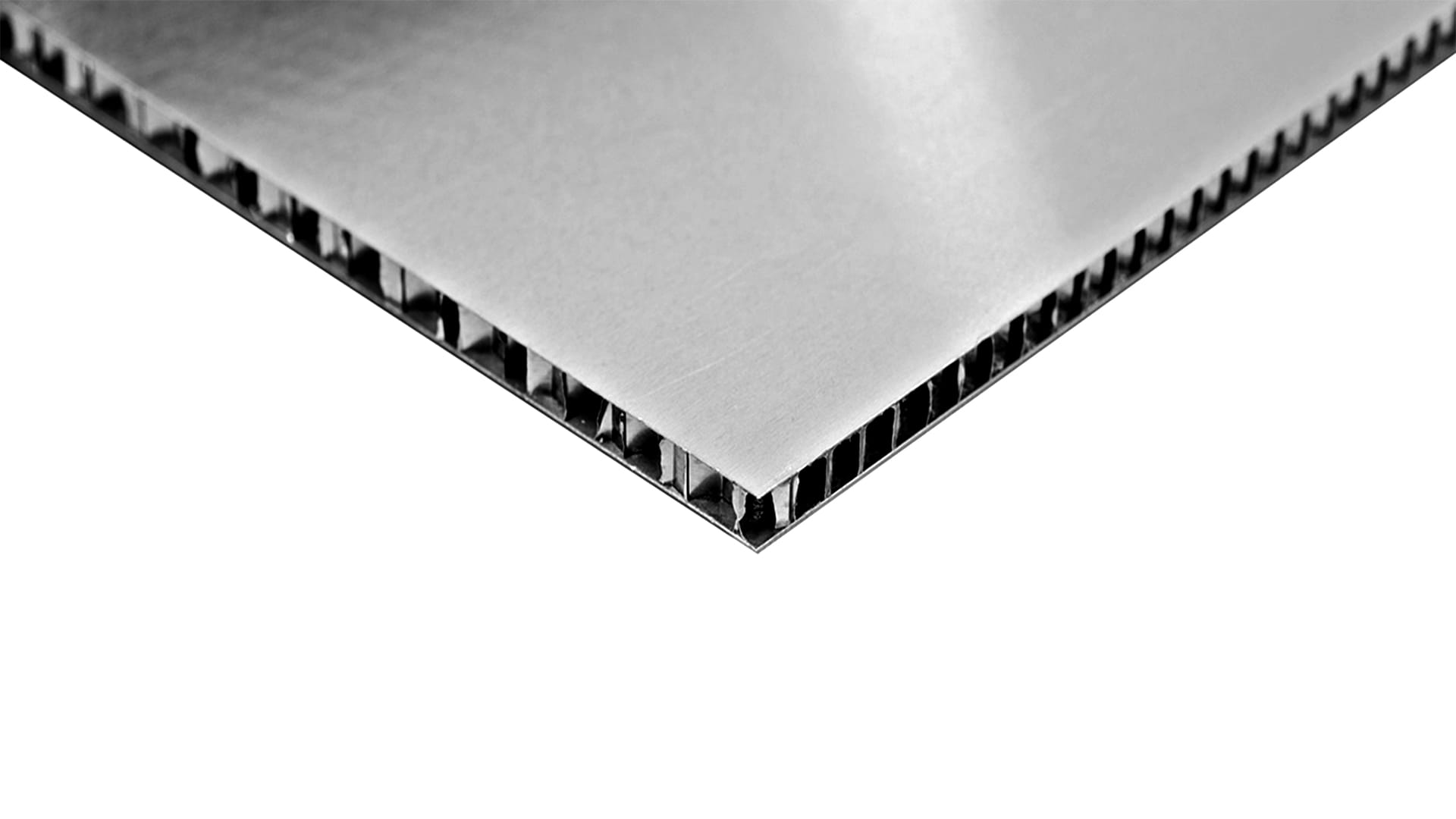

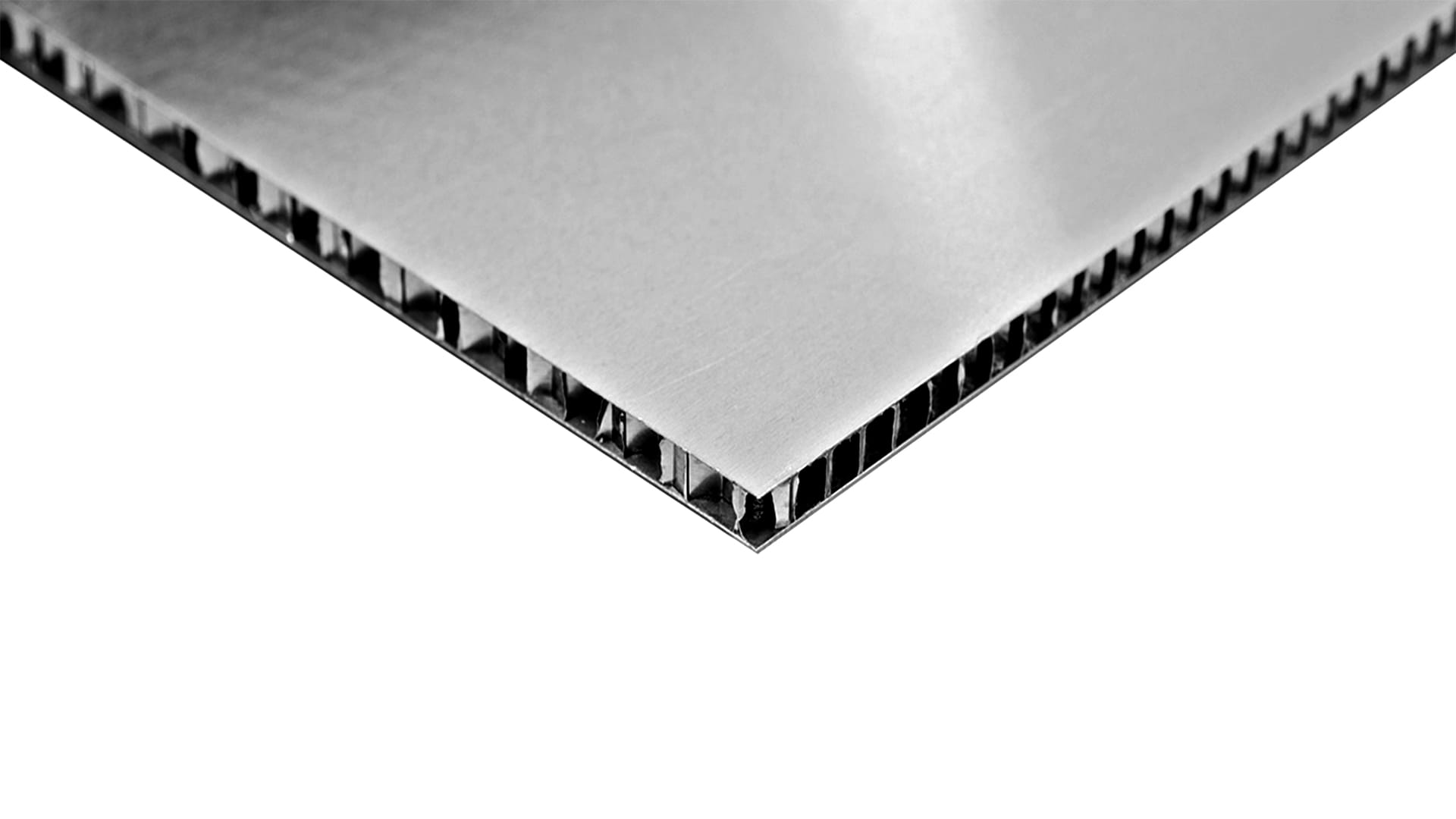

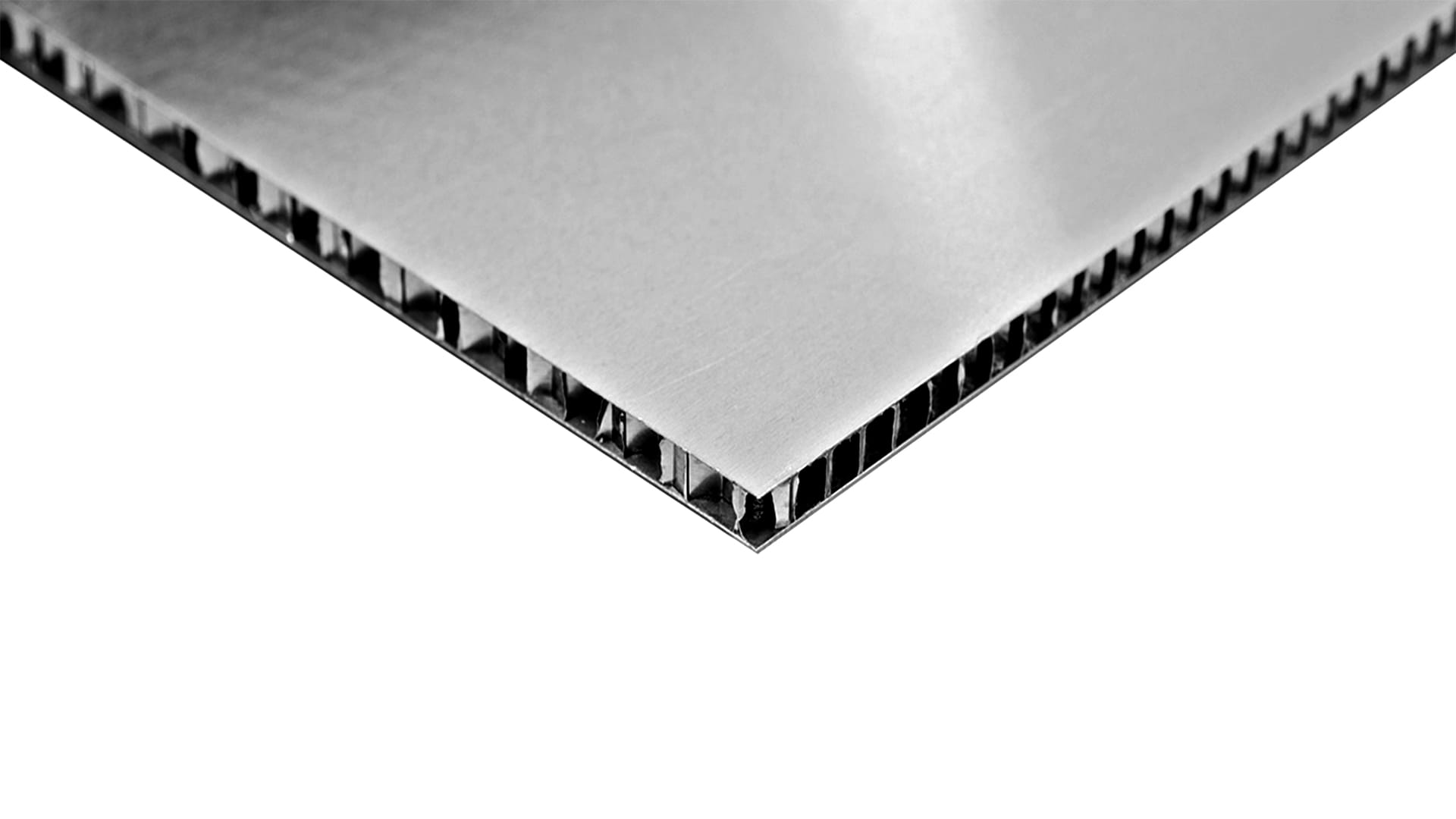

Honeycomb panels

Ensure aircraft interior structures meet strength and durability requirements with Collins Aerospace's aeroMETAL™ aluminum honeycomb panels. aeroMETAL panels are designed to meet the highest levels of quality and durability requirements in the industry.

With a wide range of panel solutions, customers have the flexibility to customize the sheet size, aluminum skin type and treatment options, meeting specific interior and structural applications needs. aeroMETAL is designed for monuments, shelving, partitions, bulkheads and more.

Features & benefits

- Available in multiple sheet sizes from 48 x 96 inches up to 60 x 144 inches (additional sizes available upon request through our aeroADD™ family

- Capability to produce panels at a thickness tolerance of ± 0.010 inch

- Available in a wide range of aluminum alloys, such as 2024-T3 and 7075-T6 – with sheet treatment options such as clad, anodized/chemical film, primer, alodine, bare and more

- Compliant with flammability requirements from FAA Code of Federal Regulations (CFR) 25.853 Appendix F:

- Part I – 60-second vertical

- Part V – National Bureau of Standards (NBS) smoke emission

- The aeroMETAL panels use:

- An aluminum skin that meets the applicable AMSQQ- A-250 specifications

- An aluminum core that meets the AMS-C-7438 specifications

- A film adhesive that meets the AMS-A-25463 type 1 specifications

- OEM qualification on select panels

Performance

- Service temperature: -67° F (-55° C) to 180° F (82° C)

- Superior elasticity

- Combination of consistency and cost effectiveness

2024-T3 Clad Skin/5052 Aluminum Core (3/16-Inch Cell) (0.020 Inch Skin)

- Flammability: Federal Aviation Regulations (FAR) 25.853 Appendix F:

- Part I – 60-second vertical

- Part V – NBS smoke emission

- Skins: 0.020-inch 2024-T3 clad

- Core: 5052 aluminum 3/16-inch cell, 5.7 pounds per cubic foot

- Standard dimensional tolerances:

- Length and width of ± 0.500 inch

- Thickness of ± 0.010 inch

- Panel dimension: 48 x 96 inches (up to 60 x 144 inches)

2024-T3 Clad Skin/5052 Aluminum Core (3/16-Inch Cell) (0.032 Inch Skin)

- Flammability: FAR 25.853 Appendix F:

- Part I – 60-second vertical

- Part V – NBS smoke emission

- Skins: 0.032-inch 2024-T3 clad

- Core: 5052 aluminum 3/16-inch cell, 5.7 pounds per cubic foot

- Standard dimensional tolerances:

- Length and width of ± 0.500 inch

- Thickness of ± 0.010 inch

- Panel dimension: 48 x 96 inches (up to 60 x 144 inches)

2024-T3 Clad Skin/5052 Aluminum Core (¼-Inch Cell) (0.020 Inch Skin)

- Flammability: FAR 25.853 Appendix F:

- Part I – 60-second vertical

- Part V – NBS smoke emission

- Skins: 0.020-inch 2024-T3 clad

- Core: 5052 aluminum ¼-inch cell, 3.4 pounds per cubic foot

- Standard dimensional tolerances:

- Length and width of ± 0.500 inch

- Thickness of ± 0.010 inch

- Panel dimension: 48 x 96 inches (up to 60 x 144 inches)

TML-7075-T6 Clad Skin 3 16 010

- Flammability: FAR 25.853 Appendix F:

- Part I – 60 -second vertical

- Part V – NBS smoke emission

- Skins: 0.010-inch 7075-T6 clad

- Core: 5052 aluminum 3/16-inch cell, 3.1 pounds per cubic foot

- Standard dimensional tolerances:

- Length and width of ± 0.500 inch

- Thickness of ± 0.010 inch

- Panel dimension: 48 x 96 inches (up to 60 x 144 inches)

TMR-7075-T6 Clad Skin 1-4 012

- Flammability: FAR 25.853 Appendix F:

- Part I – 60-second vertical

- Part V – NBS smoke emission

- Skins: 0.012-inch 7075-T6 clad

- Core: 5052 aluminum ¼-inch cell, 4.3 pounds per cubic foot

- Standard dimensional tolerances:

- Length and width of ± 0.500 inch

- Thickness of ± 0.010 inch

- Panel dimension: 48 x 96 inches (up to 60 x 144 inches)

Product Development and Application Engineering Services

From concept design through qualification, Collins Aerospace's engineers will apply their expertise to offer the right solution based on the operators’ needs. The process starts with the initial step of evaluating the properties of the materials in the existing configuration. Subsequently, we offer alternate solutions that reduce weight, increase strength and/or reduce cost. Collins Aerospace's established relationships with a wide variety of material suppliers help ensure that your panel materials are ideally suited for your unique application.