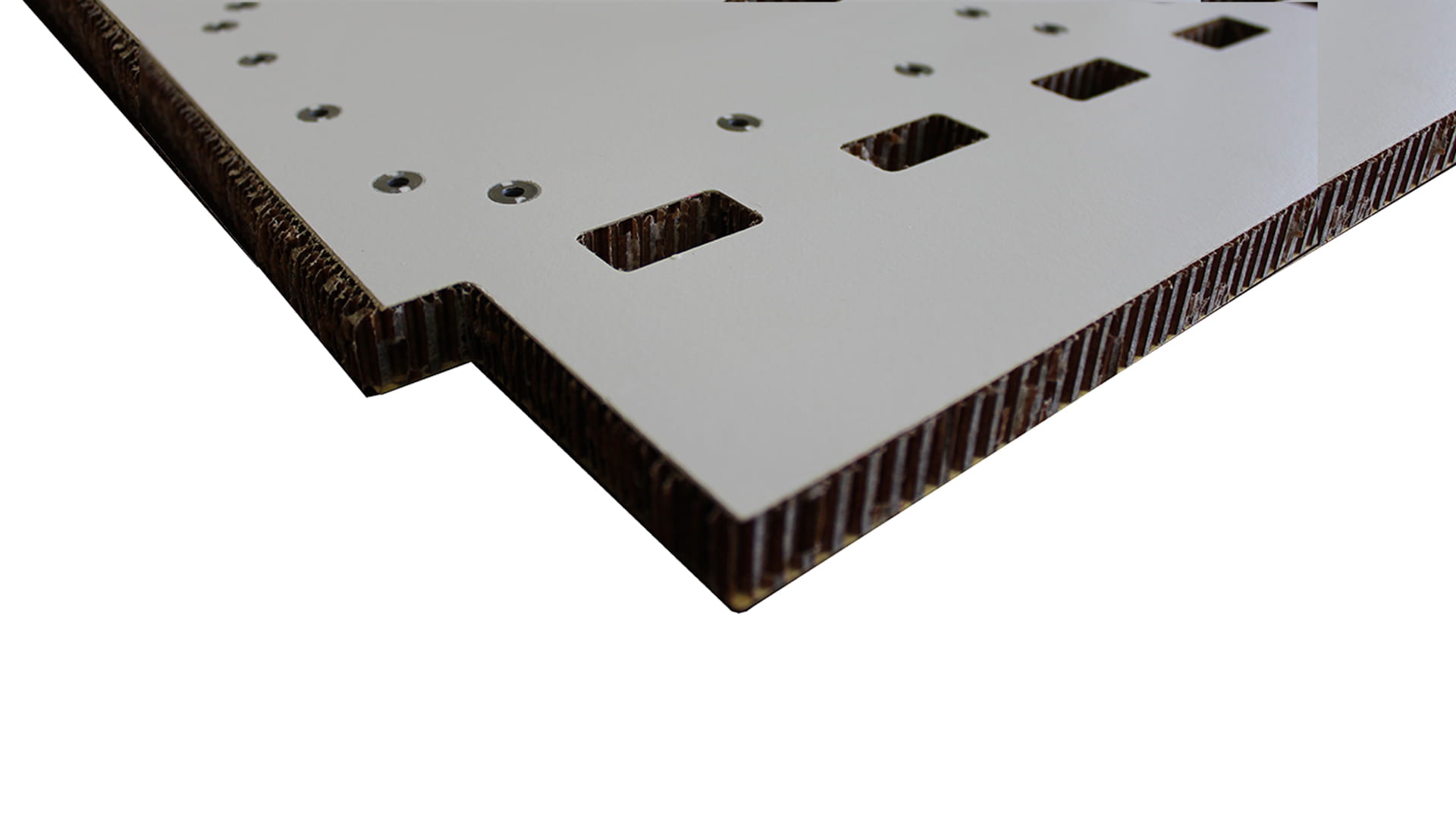

Honeycomb panels

Realize the convenience, expertise and choices needed with Collins Aerospace's aeroADD™ value-added operations. aeroADD operations are available for all aircraft structural panels product lines – standard or custom. Not only do airlines benefit from complete tooling and manufacturing capabilities, Collins is also able to integrate all of required inserts and/or other special features, perform required unique cuts and other operations necessary to prepare panels for installation.

Value-Added Operations

Collins Aerospace's value-added operations are designed to meet a broad range of specific drawing requirements. Equipped with computer numerical control (CNC) machines and ovens, a variety of secondary operations can be performed. These value-added operations include but are not limited to: insert installation, edge sealing, cut and fold and embedded detail within the panel.

Collins Aerospace offers the extensive experience necessary to manufacture curved panels using a hand-layup process. When necessary, custom tools can be procured or provided by the customer to generate the required unique shape and form of the panel.

Features & benefits*

- On-site panel manufacturing and value-added services to enhance logistics, providing a one-stop shop for customers

- Can be designed to meet all flammability requirements of FAA Code of Federal Regulations (CFR) 25.853 Appendix F:

- Part I – 60-second vertical

- Part IV - Ohio State University (OSU) heat release

- Part V - National Bureau of Standards (NBS) smoke emission

- Wide range of tools to enable:

- CNC routing

- Edge closeouts including edgefill, extrusions, bars or tapes

- Insert installation

- Cut and fold

- Curved panels using hand layup process

- Embedded details

- Available in custom sheet sizes

*For specifications, please refer to our panel families.

Performance

The resulting mechanical properties can be provided once desired combinations have been selected.

Product Development & Application Engineering Services

From concept design through qualification, Collins Aerospace's engineers will apply their expertise to offer the right solution based on the operators’ needs. The process starts with the initial step of evaluating the properties of the materials in the existing configuration. Subsequently, we offer alternate solutions that reduce weight, increase strength and/or reduce cost. Collins Aerospace's established relationships with a wide variety of material suppliers help ensure that your panel materials are ideally suited for your unique application.