As one of the world’s leading suppliers of nacelle systems, we are constantly investing in critical research and development activities to develop advanced architectures, more efficient noise attenuating technologies, novel material systems and lean manufacturing processes. These technologies enable lightweight, low drag architectures, capable of making aircraft more environmentally friendly through increased fuel efficiency and significantly reduced engine noise. With 80 years of experience and certification of 19 modern nacelle programs over the last decade – we know nacelles.

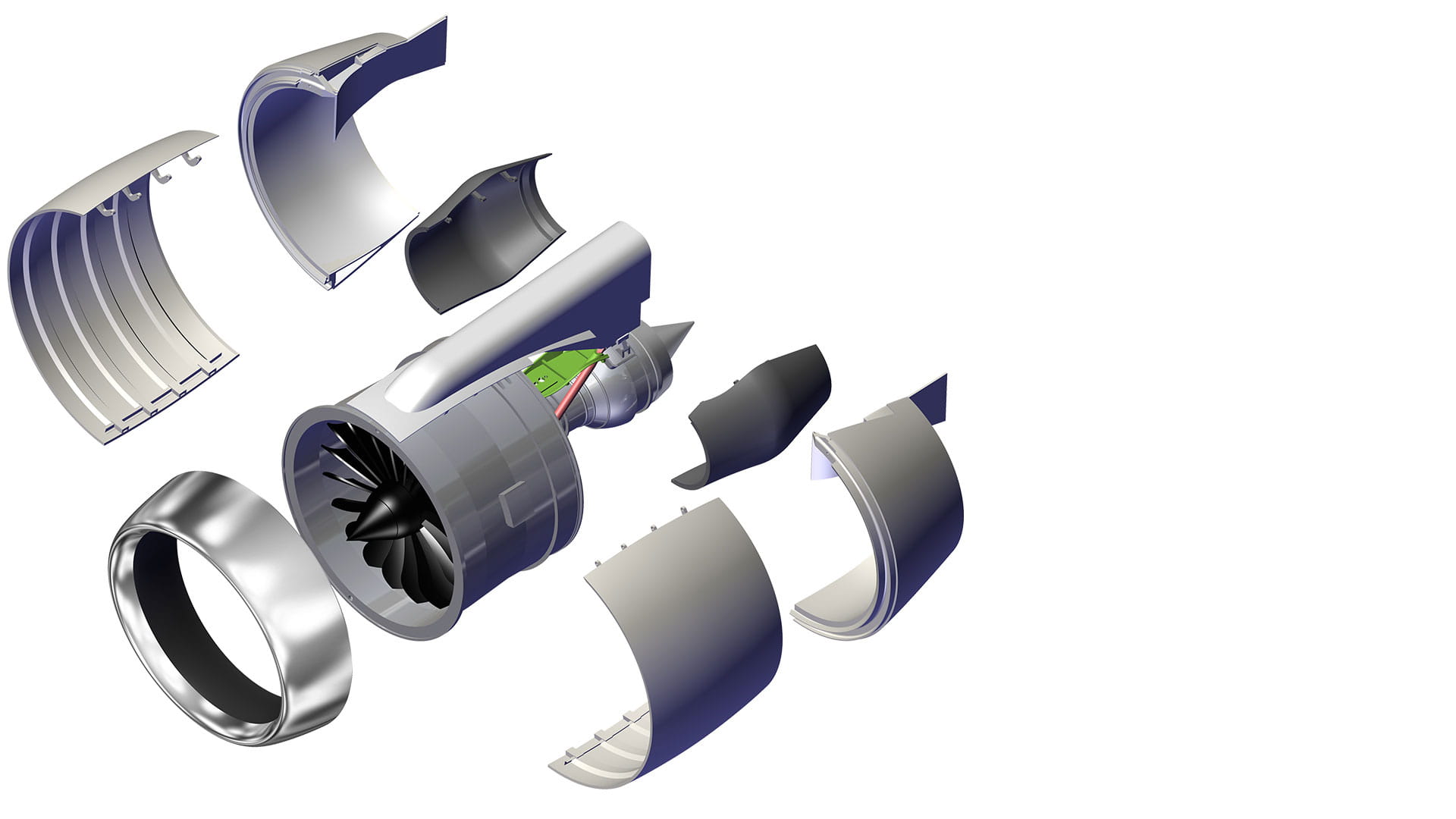

Complete nacelle system design

We have the capability to design and manufacture the full aerodynamic structure that surrounds a jet engine.

Our nacelle system integration expertise goes into designing optimized solutions for every component of the nacelle from inlet cowl, fan cowl and thrust reverser, to engine exhaust. We don’t just stop at the structure – our expertise includes the design and integration of mechanical systems like the ice protection system, door opening system and thrust reverser actuation. We are also the engine buildup provider of choice for programs from today’s leading engine manufacturers.

As technology continues to evolve, we invest a significant amount of research and development funds into developing new technologies. These technologies are focused on making planes go further while reducing fuel burn, emissions and noise for a more sustainable future.

Hover over the nacelle components shown below to see examples of how our next-generation nacelle technologies are redefining aerospace.

Thrust reverser

Hidden link reverser

Patented designs improve performance with removal of drag links and lower bifurcation.

Translating sleeve

Thermoplastic or epoxy

Low drag liners enables significant reduction in fuel burn.

Exhaust system

Titanium, Inconel, or Ceramic Matrix Composites

Patented advanced acoustic treatment solutions.

Inner fixed structure

Titanium LID or Composite

Proprietary titanium LIDBond™ enables elimination of thermal protection and improved durability.

Fan cowl

"Hollow hat" thermoplastic or epoxy

No honeycomb core for damage tolerance and ease of repair.

Shhh…

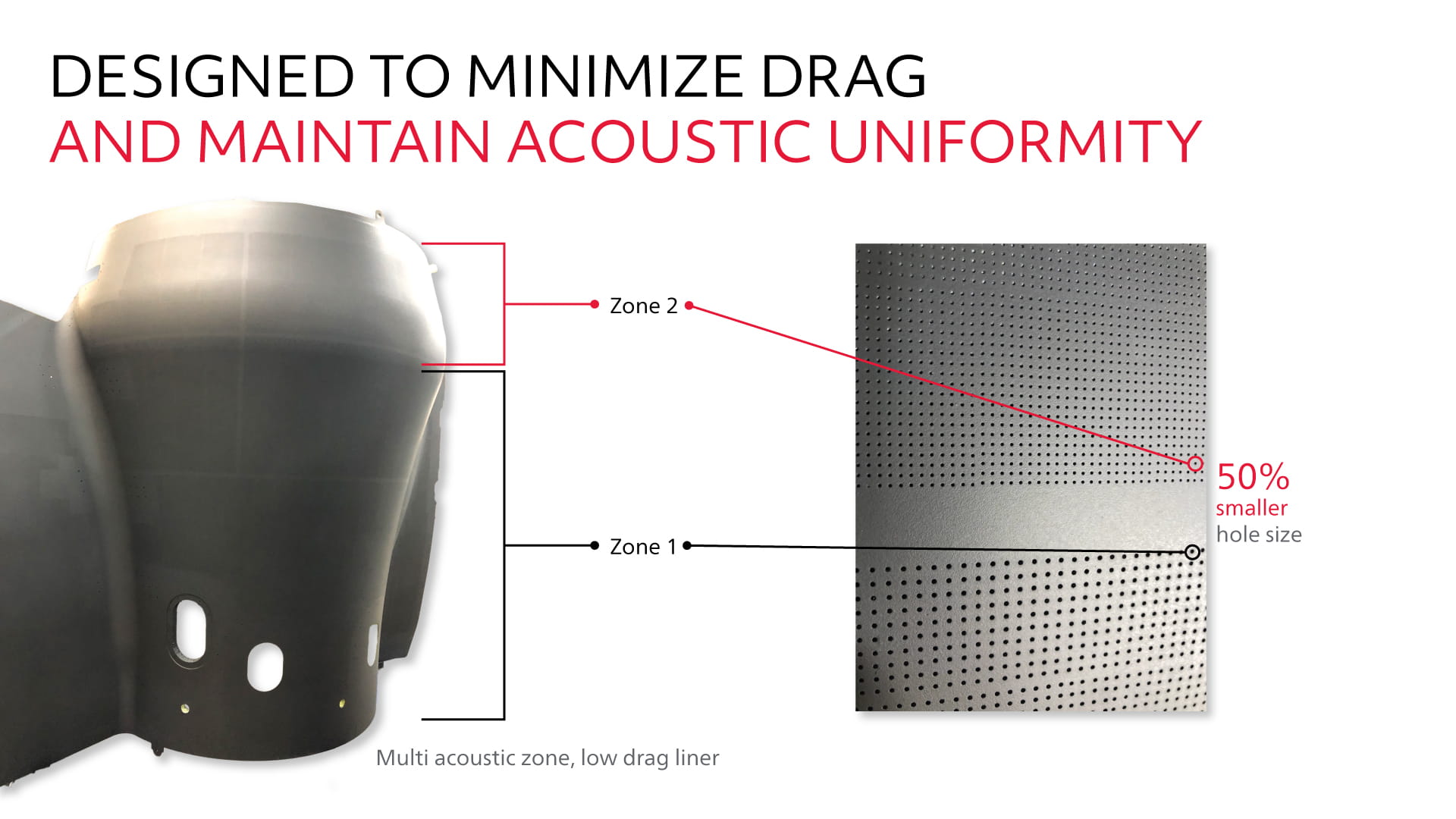

Our advanced acoustic technologies don't just support the stringent noise reduction requirements for next-generation aircraft, but also reduce fuel burn.

Our APT (Advanced Perforate Technology) is just one of the many technology implementations that we are applying to improve aircraft sustainability. With APT, we can produce repeatable, small hole perforations, which reduces aerodynamic drag and improves noise attenuation for nacelle inlets and thrust reversers.

Count on us

Our nacelle systems have 99.99% dispatch reliability, backed by an industry-leading service and support network

Leading customer support capability

Collins' excellence in aftermarket support is achieved through its global infrastructure and industry network. Collins has been a direct supplier to the commercial aviation operators for 40 years aligning its resources to provide its services to customers when they need them, where they need them.

The current Aerostructures customer support organization comprises over 1,400 customer support professionals around the world in 9 countries, and 10 facilities. Collins' global footprint supports spare parts, technical support, rotable assets inventory, integrated services (FlightSense®), and extensive capabilities at our maintenance, repair and overhaul (MRO) locations.

Our strategically placed MRO facilities ensure customer access to services when they are needed most. Collins collaborates with our customers to establish a management plan that ensures the highest dispatch reliability at the lowest cost of ownership through inventory holding and rotable programs, predictable maintenance costs, and enhanced service levels that meet the needs of your fleet.

Contacts

+1.619.691.2089