Collins Aerospace leads the way in thermoplastic composite manufacturing

Thermoplastic composites are making an impressive mark on the aerospace industry today. Manufacturers are achieving reduced manufacturing cycle times of 80 percent, products are up to 50% lighter compared to earlier iterations and sustainability is far more advanced than we’ve seen in years past.

What are thermoplastic composites?

Thermoplastic composites are getting a lot of attention these days as the aerospace industry increasingly uses them to replace various metallic and thermoset composite parts.

The future of aerospace is...plastics?

In a famous quote from the timeless 1967 movie "The Graduate," a young Dustin Hoffman receives some prescient advice. His father's friend tells him about the path to future success: "One word…plastics." Few would have believed then that even airplanes would one day be built out of plastics.

Fly lighter, with less fuel

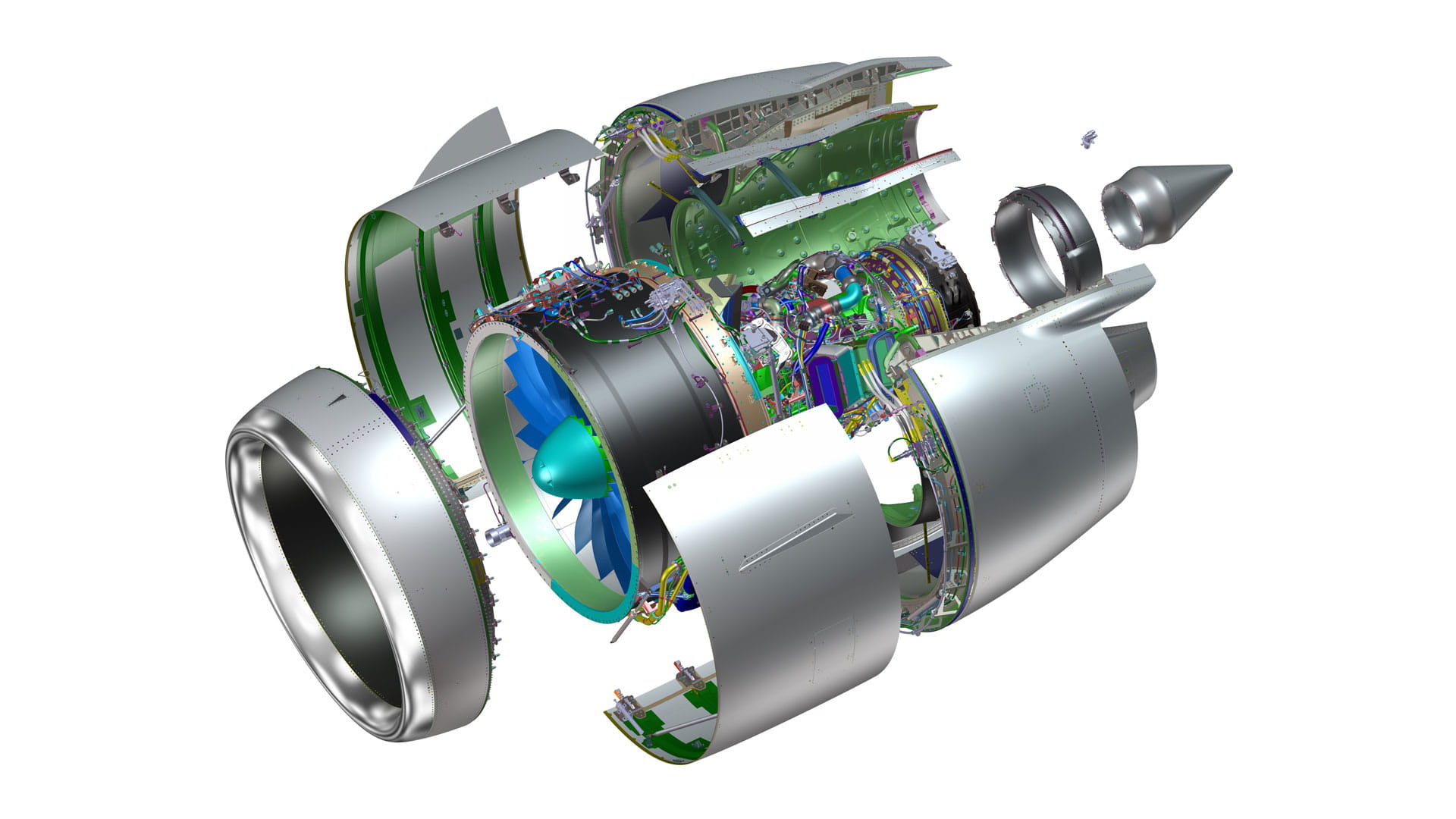

Aircraft structures made with thermoplastic composites can reduce operating costs and make flight more sustainable.

We’re advancing innovative materials and breakthrough technologies to create lighter weight, more sustainable components – from the smallest brackets to even larger, complex fan cowls – to reduce the overall weight of an aircraft. And lighter means more fuel-efficient. With automated manufacturing and integrated thermoplastic composite structures, we can help you fly lighter – and shape a more sustainable future along the way.

Superior weight savings

Up to 50% weight reduction compared to metallic structures and 20% lighter than thermoset structures

Unmatched expertise

20+

100+

2k

20

Supported aircraft platforms – and growing

Sustainable solutions in less time

Up to 80% reduction in manufacturing cycle time compared to thermoset

Potential for 100% recyclability at the end of its lifecycle

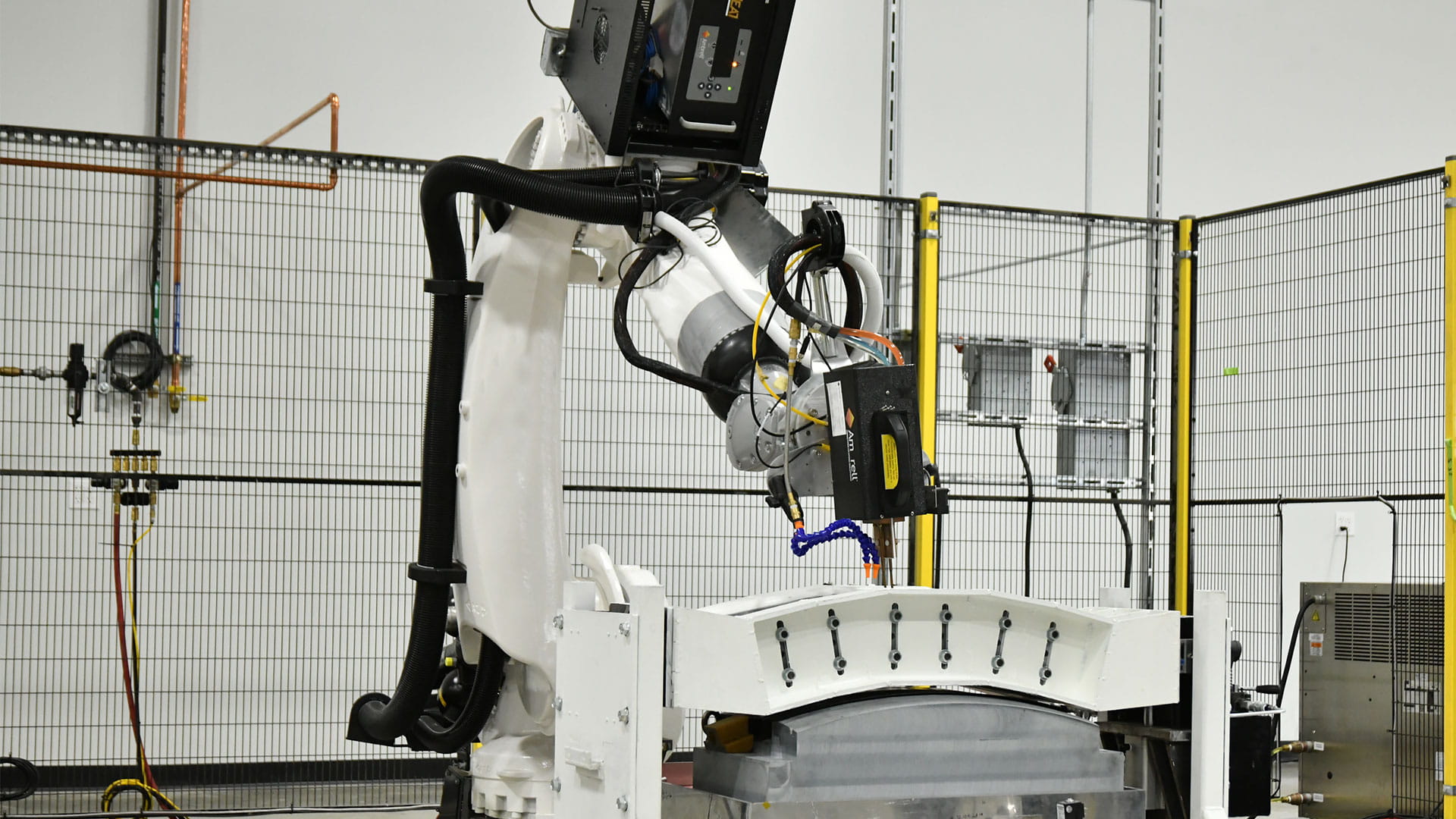

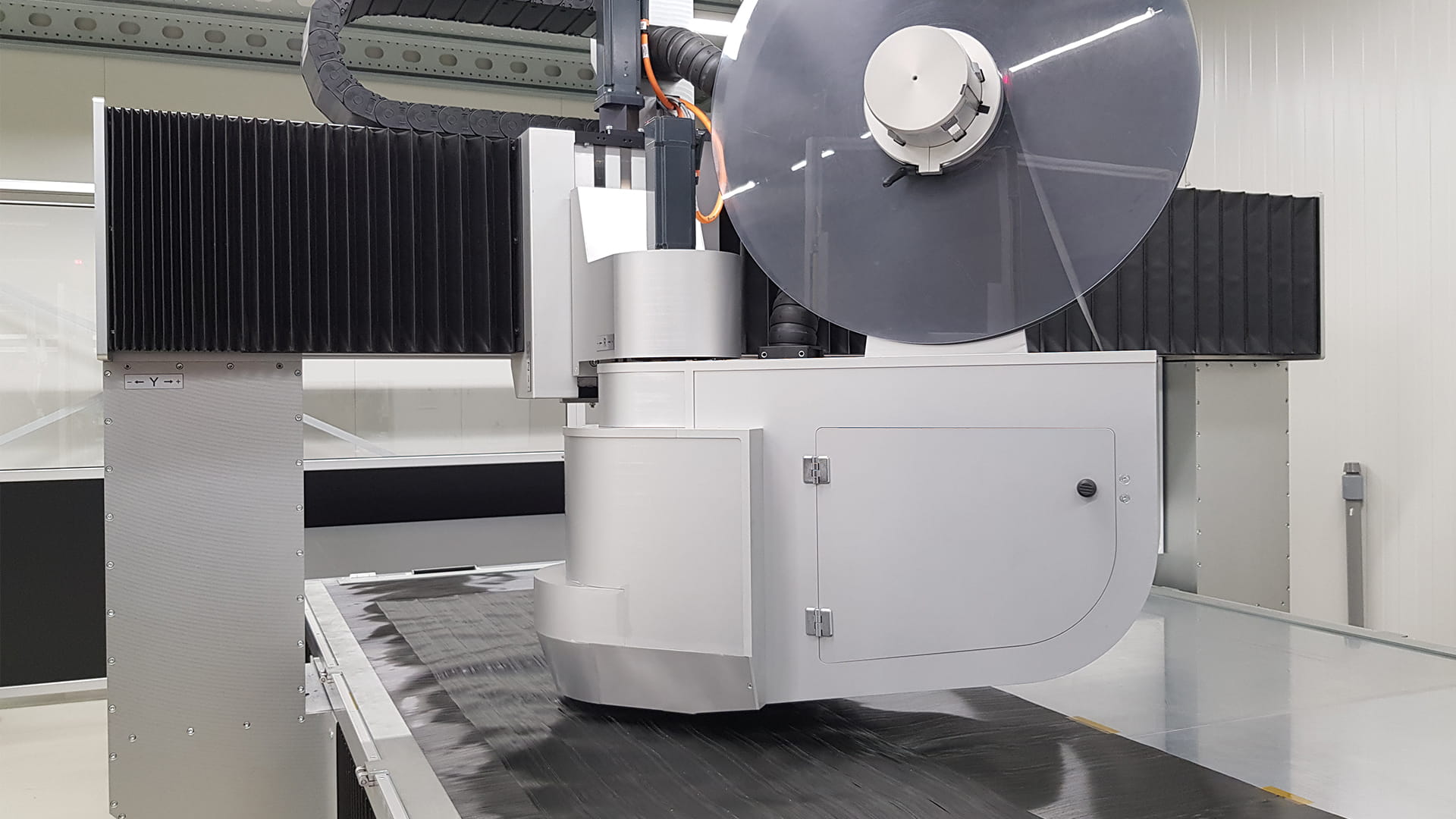

Advanced manufacturing technologies

R&D

20+ research and development centers

Facilities

~70k sq. ft. of manufacturing and office space

Tech

8 stamp forming presses

10 CNC trim stations

4,200 tools created

High-temperature flexibility

700° F temperature to mold materials

<400° F operating temperature

Thermoplastics news from around the web

- Welding is not bonding (CompositesWorld, Nov. 2023)

- The potential for thermoplastic composite nacelles (CompositesWorld, Nov. 2023)

- Collins Aerospace demonstrates new thermoplastic composites capabilities (CompositesWorld, Sept. 2022)

- Collins puts thermoplastics to good use (Nation Shield, April 2022)

- The future of aerospace is…plastics? (FlightGlobal, February 2022)

- Collins Unveils Advanced Structures, Including Dutch Thermoplastic Unit (Aviation Week, January 2022)

- Collins acquires Dutch Thermoplastic for undisclosed sum (FlightGlobal, November 2021)