Cabin Air is Cleaner Than You Might Think

Historically, airline passengers may not have given a second thought to the air they breathe while on an airplane. Yet as people begin to fly again during COVID-19, cabin air quality is now top of mind for many. A recent Harris poll found that “even after the government signals that COVID-19 is abating… only about half of Americans (49%) think they’ll be ready to fly” within the following six months. Fortunately, the Air Management Systems team at Collins Aerospace has decades of experience in designing and manufacturing cutting-edge systems to keep cabin air clean.

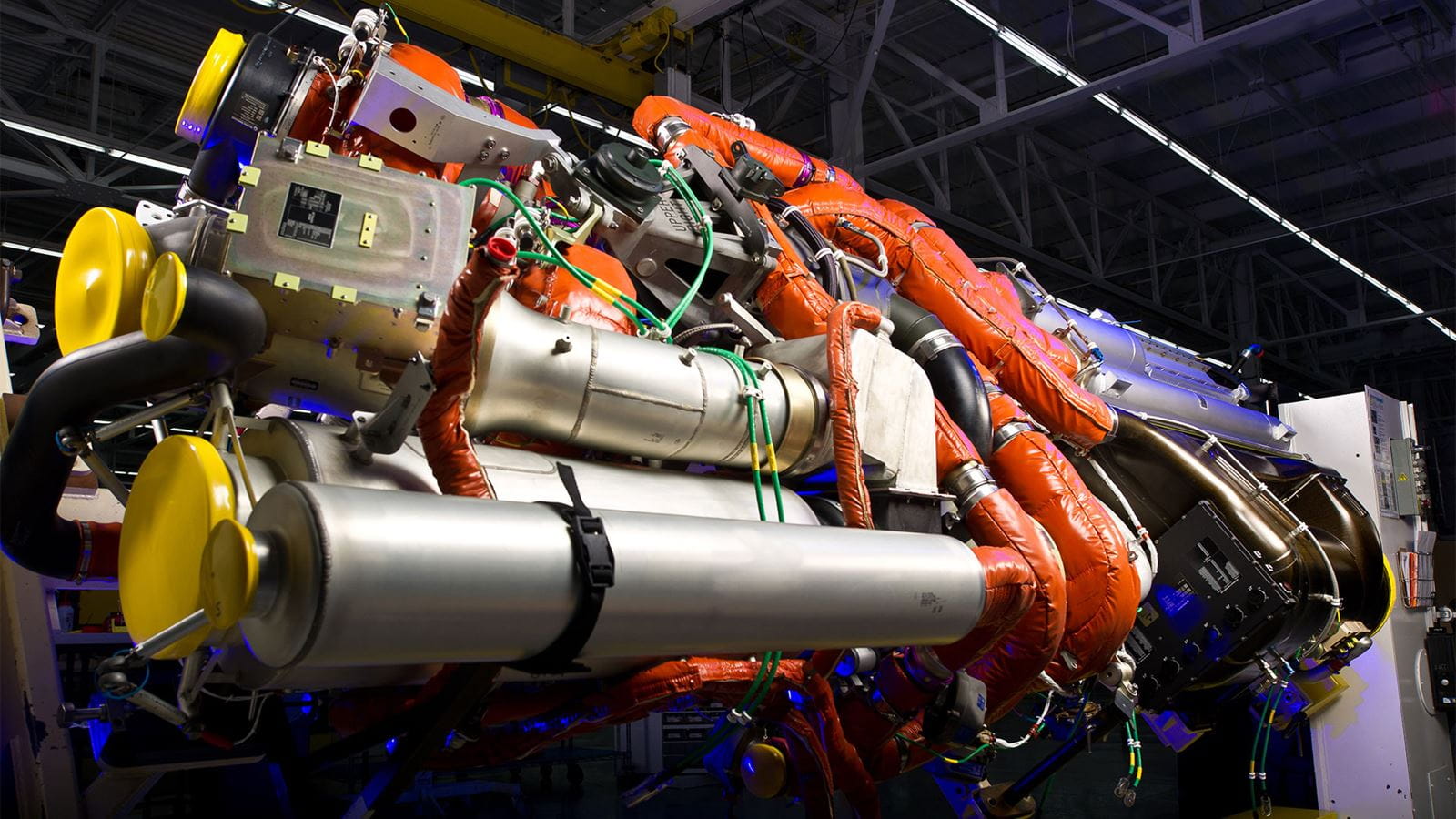

From its first environmental control system for the North American F-86D SabreJet in 1949 to its more electric ECS for the Boeing 787, Collins Aerospace has been providing passengers with safe, healthy and comfortable cabin air for more than 70 years. With air management systems onboard thousands of commercial aircraft, chances are you’ve been on a flight that’s been air conditioned, pressurized and ventilated by Collins Aerospace. During the coronavirus, however, it’s ventilation and sanitation that have become the team’s key areas of focus.

“What most people don’t realize is that the air delivered to an aircraft cabin is of very high quality and has been for many years,” said Lee Annecchino, vice president for Air Management Systems at Collins Aerospace. “In fact, the air supplied to a large commercial aircraft that uses a HEPA filter in its ECS can be as clean or cleaner than the air in a hospital operating room.”

The keys to clean cabin air include high rate of fresh air flow, High Efficiency Particulate Air filters, commonly called HEPA filters, and the design of aircraft airflow distribution.

The biggest factor in cabin air quality is the inflow of fresh air. Aviation regulatory authorities such as the Federal Aviation Administration and European Aviation Safety Agency require a minimum rate of 0.55 pounds per minute outside fresh air flow per occupant. In a large commercial passenger aircraft, that means a typical environmental control system may replace the air occupying the cabin every 2 to 3 minutes –20 to 30 times per hour. By comparison, the general guidance on fresh air inflow for buildings is only 4 changes per hour.

In most of today’s environmental control systems for large commercial aircraft, such as Collins Aerospace’s ECS for the 787, the fresh air inflow is mixed with recirculated cabin air. The recirculated cabin air is passed through HEPA filters to remove particulates such as dust and mitigate the transmission of bacteria and viruses. HEPA filters have a higher filtration efficiency rating than “N95” respirators and are the same filters used in hospital protective environments.

In addition to filtering and regularly replacing cabin air, aircraft environmental control systems also distribute air flows from ceiling to floor – not front to back. This helps reduce the spread of unfiltered, contaminated air.

While all three of these elements have been common to aircraft environmental control systems since the 1990s, Collins Aerospace is now looking for ways to use the cabin air distribution system to further increase cleanliness in response to COVID-19, while reducing the burden on airline maintenance personnel. Methods under consideration include using the air distribution system to inject cleaning agents such as hydrogen peroxide or ozone into an empty cabin between flights, Annecchino said.

“Right now, maintenance teams are manually cleaning cabin surfaces between flights as part of a process that can be labor-intensive and time-consuming,” Annecchino said. “If we can develop a way to automate it with the ECS, we could help our airline customers save time and boost efficiency while giving their passengers greater peace of mind.”

As passengers return to the skies, Annecchino has a simple message.

“While no precautionary measures can ever guarantee against the transmission of pathogens, passengers should know that when it comes to the air supplied onboard a plane, there are numerous technologies at work to keep it safe and clean.”