3D Printed Face Shields in the Age of COVID-19

At one time or another, we’ve all proudly displayed motivational quotes on an office or manufacturing facility wall. Some of the best of these quotes are:

- “No man is an island.” John Donne

- “There is no ‘I’ in team.” Peter Drucker

- “Your attitude determines your altitude.” Zig Ziglar

At first blush, these quotes can appear a little stale. Yet look at them with fresh eyes. Whether consciously or subconsciously, the 78,000 men and women of Collins Aerospace are living these insights today and bringing light to one of the darkest chapters in world history.

Recently, Paula Hay, vice president, Operations, Collins Aerospace, received a request from Paolo Dal Cin, head of operations for Raytheon Technologies, to determine if 3D printers across the global enterprise might be used in the life and death struggle against COVID-19.

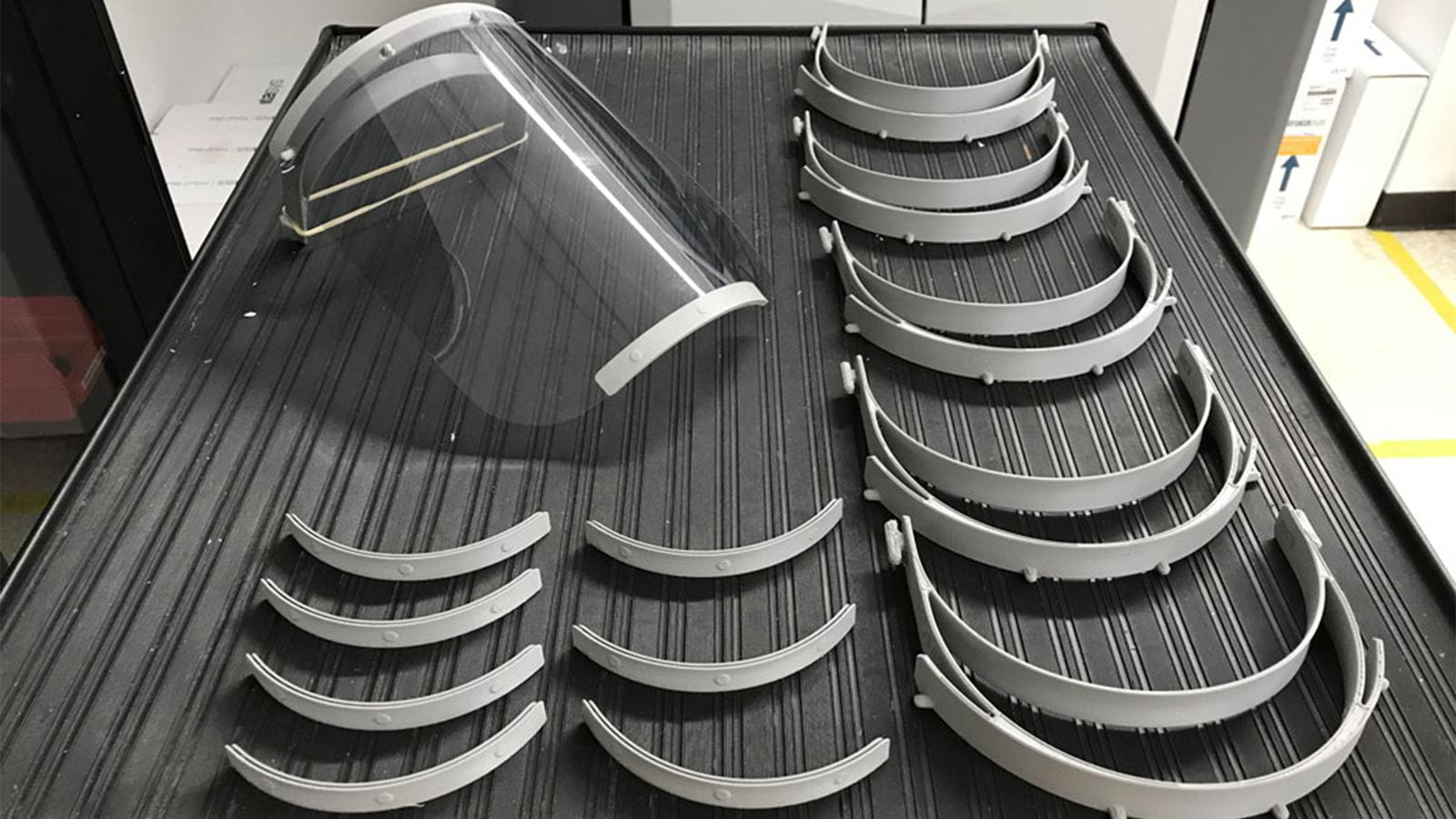

In particular, Paula was asked if it might be possible to 3D print headbands for face shields that are in shockingly short supply for frontline warriors—doctors, nurses, and other healthcare professionals.“I’d been reading about how medical-grade face masks are almost impossible to find,” said Paula. “When I learned that healthcare professionals are practically begging for face shields that protect workers from their patients, it was just an automatic response. We’re going to make this happen!”

Paula reached out to Collins’ global sites that do 3D printing for the aerospace and defense industry. The response was immediate. Just tell us what you want. Give us the specs. We’re ready!

Thousands of Collins’ engineers raised their hands to help, including Alex Bosworth, a research engineer in Additive Manufacturing, located in Windsor Locks, CT. Alex runs a 3D printer and is all in for helping to 3D print face shields.

“Our whole team couldn’t wait to begin printing parts for the face shields,” said Alex. “The thought that doctors and nurses are risking their lives every day … we knew we were in a position to help, so we got to work. We wanted to help those actively helping other families so that they could be around for their own families.”

According to Paula, nearly 70 3D printers across Raytheon Technologies global locations are working to produce face shield headbands. The goal is to produce 2,500 headbands a week that will be distributed to multiple health and emergency response organizations who will then distribute them to hospitals and healthcare workers.

“What we’ve heard from multiple organizations,” Paula emphasized, “is that we are one of the first companies to deliver these crucial face shield headbands with a robust supply chain and logistical strategy supporting them. So we’re quickly and efficiently getting this product to the healthcare workers who need it.”

It’s easy to pass over motivational insights. But it’s time to give them a fresh look. Because we’re living them right now:

- Each of us is part of an interdependent global community.

- A team achieves its greatest success when it suppresses individual egos.

- A positive attitude lies at the foundation of victory over seemingly impossible odds.

And because Alex, Paula and thousands of our colleagues across Collins, Pratt & Whitney, and the greater Raytheon Technologies are living these insights—we’re helping to save lives.

Perhaps Paula shared the perfect coda. “We are so grateful to our colleagues. We’re all in this together, and their response is a testament to the DNA of our organization.”

# # #

* We know that throughout the world there is a need for personal protective equipment. We are currently working through local government and public health officials, as well as emergency response organizations to identify how and where the face shields are being distributed.