Eliminate the pains of improper fit - in less time

Broken visor? Suffering from hotspots, headaches or neck fatigue? Collins Aerospace pilot helmet fitting solutions provide onsite and in-field customization to eliminate pilot discomfort faster.

| Military pilot helmet fitting solutions | Benefits |

|---|---|

| 3D handheld scanner |

|

| Final pilot scanning process |

|

| Final fitting process |

|

| Other benefits |

|

Customizable solutions

Mobile Scanning Service (MSS™)

A Collins technician will fly to any location and complete the full scan using our portable scanner. In less than three minutes, you will have high quality scans with increased accuracy due to color-map surface capability, enabling the scanner to identify the subject’s pupil center for positioning in the helmet. In support of future needs, full body scanning provides measurements for various masks and below-the-neck pilot-fit-equipment.

Pilot Readiness Facility (PRF™)

In less than 12 hours*, your pilot will walk out with a comfortable, high quality, customized helmet ready to use from your own pilot readiness facility.

Our facility contains the VT-CIMS™ mill, handheld scanner and all necessary fixtures and tooling needed to perform complete pilot above-the-neck (ATN) fittings. With your PRF™, nothing leaves your facility. Your designated Collins Aerospace technician will perform the scanning/milling process and complete the final fitting process, including the O2 mask, visor trimming, and web tacking.

Collins Milling Service (CMS™)

Using your personnel and scanner to perform the scans, the raw scan files are sent to us for conversion and milling in a Collins Aerospace CMS™ facility. The final fitting process can be performed by either our technicians or your personnel. If a spare handheld scanner is not purchased, Collins can provide access to a loaner scanner in the event of equipment failure.

CMS™ includes one of these options:

- 2-week on-site training course in the use of the handheld scanner

- 4-week training course on scanning and fitting procedures, depending on final fitting personnel

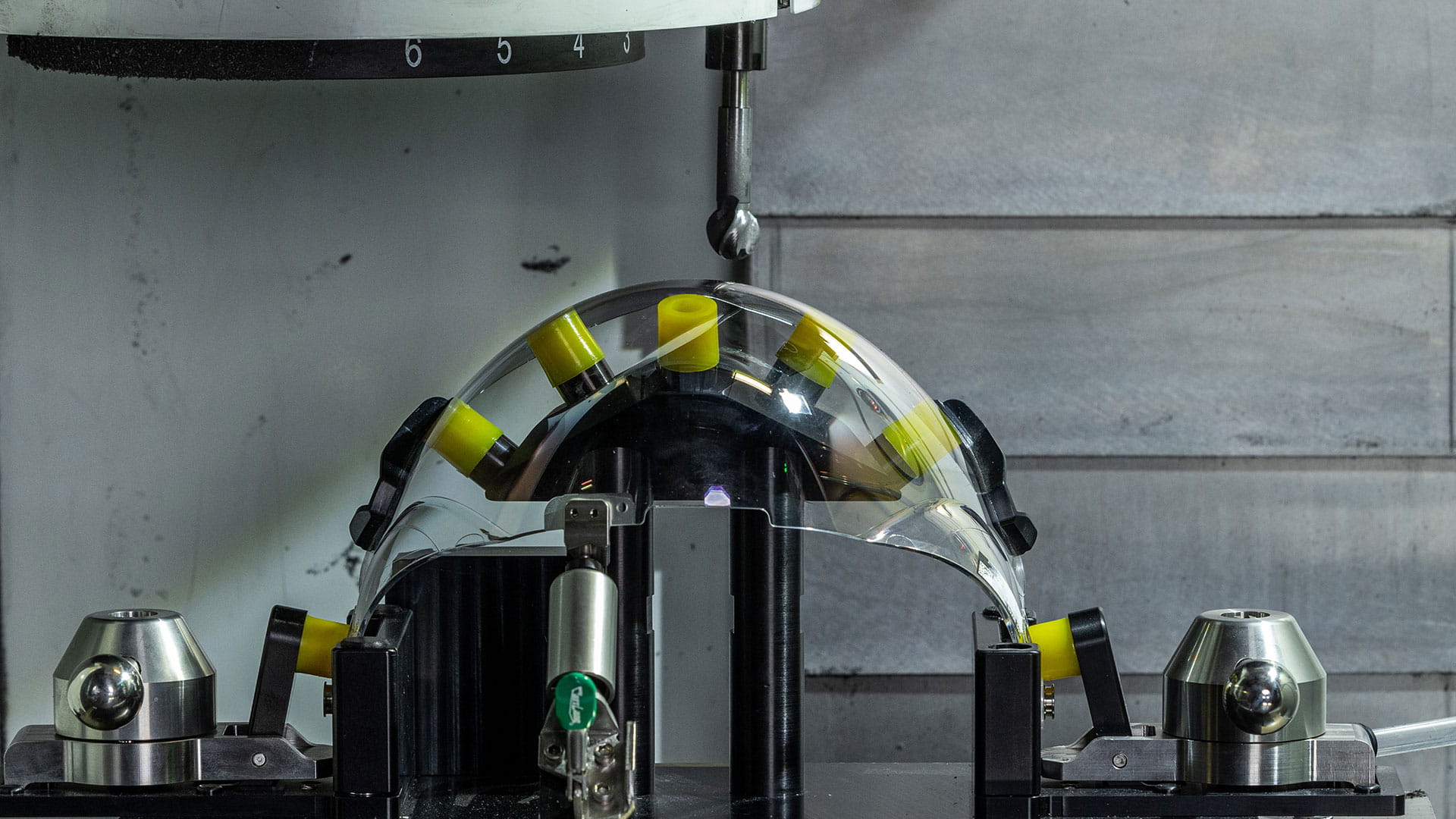

Visor Trim – Custom Insert Milling System (VT-CIMS™)

Complete the final fitting process and receive your visor and helmet pad in hours using the saved images from your one-time head scan and our VT-CIMS™.

- Decrease preventative maintenance costs

- Reduce error with real-time pilot fitting

- Compatible with the legacy visor mill

- 6-week on-site training course available

Scan database for remote milling

Save time and eliminate the need for pilots to travel or wait to be scanned. If you need to mill replacement inserts, your saved raw scan files are sent to Collins Aerospace for conversion and milling in our CMS facility.

* Requires prepositioned assets

Request information

I would like more information about this capability.